Helpful Tips and How too`s

- Fixing a Puncture on the roadside

- Fixing a snapped chain on the roadside

- Properly Lubricating your bike

- How to properly set your bike up tubeless

- Fully assembling a bike out of the box

Fixing a puncture at the roadside

Fixing a puncture at the roadside is a useful skill to have as a cyclist. It's something that can happen to anyone, and being able to fix it quickly can save you from a long walk home. Here are the steps to follow to fix a puncture at the roadside:

1. Identify the puncture: The first step is to locate the puncture. You can do this by running your fingers along the tire to feel for any sharp objects or by listening for the sound of air escaping.

2. Remove the wheel: Once you've identified the puncture, you'll need to remove the wheel from the bike. Flip your bike upside down or lean it against a wall to make this easier. Depending on your bike, you may need to use a wrench to remove the wheel.

3. Remove the tire: Use a tire lever to pry the tire away from the rim. Insert the lever between the tire and the rim, and then use it to lift the tire up and over the rim. Work your way around the tire until it's completely removed from the rim.

4. Remove the inner tube: Once the tire is off, remove the inner tube from the tire. You may need to loosen the valve nut and pull the valve out first.

5. Find the puncture: Inflate the inner tube slightly and listen and feel for the escaping air. Once you've found the puncture, mark it with a pen or marker.

6. Patch the puncture: Use a puncture repair kit to patch the hole. Roughen the area around the puncture with sandpaper, then apply the adhesive and patch. Wait a few minutes for the adhesive to dry before re-inflating the inner tube.

7. Reassemble the tire: Put the inner tube back inside the tire and then carefully work the tire back onto the rim, making sure the tube is not pinched between the tire and the rim.

8. Reinstall the wheel: Carefully insert the wheel back into the bike and tighten the bolts or quick-release mechanism.

9. Inflate the tire: Use a pump to inflate the tire to the recommended pressure, and then check the tire for any additional punctures or damage.

With these steps, you should be able to fix a puncture at the roadside quickly and easily, allowing you to get back on the road in no time.

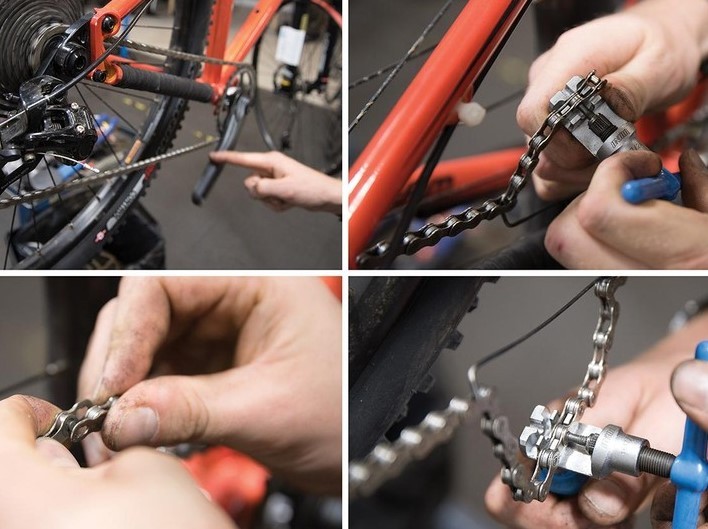

Fixing a snapped chain on the roadside

A snapped chain is a bit more challenging to fix on the roadside than fixing a puncture, but it's still possible with a few basic tools and some know-how. Here are the steps to follow to fix a snapped chain on the roadside:

1. Remove the chain: Use a chain breaker tool to remove the damaged section of the chain. Most chain breakers have a pin that pushes out the damaged link. Be careful not to push the pin all the way out, as you'll need it later to re-join the chain.

2. Remove the damaged link: Once you've pushed the pin out, remove the damaged link from the chain.

3. Reconnect the chain: Reconnect the chain by inserting the chain breaker tool back into the hole and pushing the pin back in until it's flush with the outer plate. You may need to wiggle the chain slightly to get the pin to line up correctly.

4. Check the chain: Once the chain is reconnected, check that it's properly aligned and functioning correctly. Give it a few turns to make sure it's running smoothly.

5. Test ride the bike: Take a short test ride to ensure that the chain is working correctly and that it's shifting smoothly. Make sure to ride slowly and carefully at first, as you don't want to risk the chain snapping again.

It's important to note that fixing a snapped chain on the roadside is only a temporary fix. You'll need to replace the damaged link with a new one as soon as possible to prevent the chain from breaking again in the future. Additionally, you should carry a spare chain or at least a quick link with you on your rides in case of a chain emergency.

Properly Lubricating your Bike

Properly lubricating your bicycle is an essential maintenance step to keep your bike running smoothly and prevent wear and tear on its moving parts. Here are the steps to follow to properly lubricate your bicycle:

1. Clean the chain: Before you apply any lubricant, it's important to clean the chain thoroughly. Use a degreaser or a chain cleaning tool to remove any dirt, grime, or old lubricant. You can also use a soft-bristled brush or a rag to clean the chain.

2. Apply the lubricant: Once the chain is clean and dry, apply a small amount of lubricant to each link in the chain. Use a lubricant that's specifically designed for bicycles and follow the manufacturer's instructions for application. Be careful not to apply too much lubricant, as this can attract dirt and grime, which can actually cause more wear tear.

3. Wipe off excessant: After applying the lubricant, wipe off any excess with a rag. This will help prevent dirt and grime from sticking to the chain.

4. Lubricate moving parts: In addition to the chain, you'll also want to lubricate other moving parts of your bike, such as the derailleur pulleys, brake pivots, and cables. Apply a small amount of lubricant to each of these parts, following the manufacturer's instructions.

5. Test ride the bike: Take a short test ride to ensure that everything is working smoothly. Make sure to shift through all the gears and test the brakes to ensure that they're functioning correctly.

It's important to note that over-lubricating your bike can be just as bad as under-lubricating it. Too much lubricant can attract dirt and grime, which can cause more wear and tear on your bike's moving parts. It's also important to regularly clean and lubricate your bike to prevent rust and corrosion from setting in.

How to properly set your bike up tubeless

Setting up a tubeless tire system can be a great upgrade for your bike, as it can provide better traction, reduce the risk of punctures, and allow you to run lower tire pressures for a smoother ride. Here's a step-by-step guide on how to set up a tubeless tire system:

1. Gather the necessary equipment: To set up a tubeless tire system, you'll need tubeless-compatible rims, tubeless valves, tubeless sealant, and tubeless-compatible tires.

2. Remove the tire and tube: Remove the tire and inner tube from your rim. If your tire is not tubeless-compatible, you may need to install a tubeless conversion kit.

3. Install the tubeless valve: Insert the tubeless valve into the valve hole on your rim, and tighten it down using the valve nut. Make sure that the valve is securely in place.

4. Mount the tire: Mount the tubeless-compatible tire onto the rim, making sure that it's seated evenly all the way around. Use a tire lever if necessary to get the tire onto the rim.

5. Add sealant: Remove the valve core from the valve stem using a valve core remover tool. Pour the recommended amount of sealant into the tire through the valve stem. Reinstall the valve core and tighten it down.

6. Inflate the tire: Use a high-volume pump or an air compressor to inflate the tire. Make sure that the tire is seated evenly on the rim, and that the bead is securely locked into place. Be sure to inflate the tire to the recommended tire pressure.

7. Check for leaks: After inflating the tire, check for any leaks by listening for air hissing out of the tire or by spraying soapy water around the tire and looking. If you find any leaks, shake the tire to distribute the sealant and re-inflate the tire.

8. Ride: Once the tire is fully sealed and there are no leaks, you're ready to ride! Keep an eye on the sealant level, and add more as needed to maintain the seal.

Setting up a tubeless tire system can be a bit tricky, but with patience and practice, it a great way to improve the performance of your bike. If you're not comfortable doing it yourself, consider taking your bike to a bike shop to have it set up professionally.

Fully assembling a bike out of the box

Assembling a bicycle can be complex task, but with the right tools and some basic knowledge, it can be done successfully. Here are the general steps for properly assembling a bicycle:

1. Unpack the bike: Begin bying your bike and laying out all the parts. Make sure you have all the necessary components, including the frame, wheels, handlebars, pedals, seat, and any other accessories.

2. Install the wheels: Start by inserting the axle into the dropouts on the frame and tightening the quick release lever or axle nuts. Then, inflate the tires to the recommended pressure and make sure they are seated properly on the rim.

3. Install the handlebars: Slide the handlebars into the stem and tighten the bolts to the recommended torque. Make sure the stem is aligned properly with the front wheel and the handlebars are straight.

4. Install the pedals: Thread the pedals into the crank arms, making sure to use the correct pedal for each side. The right pedal should be threaded clockwise, while the left pedal should be threaded counterclockwise.

5. Adjust the brakes and gears: Adjust the brake and gear cables to ensure smooth operation. Make sure the brakes are centered and the pads are properly aligned with the rim. Adjust the derailleur so that the chain moves smoothly between the gears.

6. Adjust the seat: Adjust the seat post height so that it is comfortable for your riding position. Make sure the seat is level and securely attached to the seat post.

7. Test the bike: Take the bike for a test ride to make sure everything is functioning properly. Check for any loose or rattling parts, and make any necessary adjustments.

8. Final check: After the test ride, perform a final check of all the components, including the bolts, nuts, and screws. Make sure everything is tightened to the recommended torque.

Assembling a bicycle can be a challenging task, but with the right tools and some patience, you can do it successfully. If you're not comfortable doing it yourself, consider taking your bike to a professional bike shop for assembly.